Mounting system types

PV modules should be attached to some kind of structure to for pragmatic reasons like preventing damage from wind and loss to due to theft, but also to ensure that the tilt and orientation is correct to maximize energy production. A typical PV module comes with an aluminum frame for the purpose of protecting the rest of the module and to provide a means for it to be secured. A PV module be secured and supported properly. Module anufacturers provide holes in the frame for mounting with bolts, that serve to identify where it is appropriate to anchor the module. There are two primary ways in which a PV module is mounted onto a structure:

- Through the bolts that are in the back of the module frame.

- Using clamps that secure the module to a rail.

In either case the module should be supported and secured in the areas where the bolt holes are in the frame otherwise it may be damaged due to weather. It is important that the module is properly tightened down regardless of the system that is used to secure it, but not to the point that it distorts the frame at all. The manufacturer will have specifications for how tight is appropriate on the specifications sheet for a module, but an installer in many parts of the world will simply have to rely upon their judgement.

Either mounting style (using the holes or clamps) can be used with a variety of different mounting systems that have different advantages and disadvantages that typically make one type the most appropriate for a given application.

Contents

Roof mount

PV modules are mounted on the roof of a home or building. This is the most typical approach around the world. The PV modules sit on rails that are anchored into A system of this type the structure that underlies the roof (perlins, timbers, etc). Clamps are used to hold the modules to rails.

Advantages

- Low cost as the roof structure already exists.

- Many roofs have lots of open space that can be used for a sizable PV system.

- No custom fabrication required.

- Limited amount of material required. Easy to transport to the jobsite.

- Simple installation. No concrete.

- Does not occupy space around the home that could be used for another purpose.

- Out of the reach of children, domesticated animals and theives.

Disadvantages

- Requires the creation of holes in the roof which can lead to leaks.

- Makes roof repairs or replacement difficult.

- Existing roof structure may not be appropriate to work on or support a PV system. It needs to be evaluated.

- The tilt and orientation of the roof is typically used and is often not optimal. This can reduce system performance.

- Roof surfaces can generate significant amounts of heat that can reduce PV module production.

- Module tilt cannot be adjusted seasonally like with a pole mount.

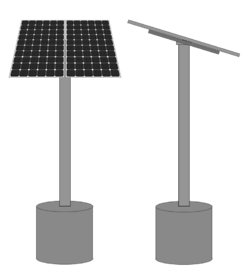

Pole mount

PV modules are mounted onto a racking structure that sits atop one or two poles that are anchored into concrete. Pole mount systems are common for small-scale off-grid PV systems as they can be installed nearly anywhere and allow the design to be optimized for the site.

Advantages

- Relatively low cost for small systems.

- Can be installed in nearly any location.

- Installation does not depend on the strength or quality of a roof.

- Angle and orientation of the PV modules can be chosen.

- Can easily be built to permit the tilt of the modules to be adjusted seasonally.

- Keeps modules cooler than a roof mounted system.

Disadvantages

- Pole mount will occupy otherwise usable space near the home.

- Installation is more involved. Requires concrete.

- Custom design and fabrication of the pole mount for the project is required.

- Transport of the pole and mounting structure can be difficult.

- Other mounting system designs are often more appropriate for larger systems.

Ground mount

PV modules are mounted onto a racking structure that sits atop four or more poles that are anchored into concrete. Ground mount systems share many of the same advtantages of pole mount systems, but work better for larger offgrid systems.

Advantages

- Can be installed in nearly any location with any size system.

- May be fabricated on site with the right design and materials.

- Installation does not depend on the strength or quality of a roof.

- Angle and orientation of the PV modules can be chosen.

- Keeps modules cooler than a roof mounted system.

Disadvantages

- Involved installation involving many different holes with concrete.

- Requires a significant amount of materials and racking that can be difficult to transport.

- Ground mount will occupy otherwise usable space near the home.

- Custom design of the ground mount system will be required.

- Not as easy to build to incorporate adjustable tilt like as with a pole mount.

Ballast mount

PV modules are mounted onto a racking structure that sits atop the ground or a flat roof surface that relies upon the weight of heavy concrete blocks to secure it rather than any type of concrete or anchors to the roof structure. Ballast mount systems are not as common with offgrid PV systems as other mounting systems, but they have a lot of advantages if the location is appropriate.

Advantages

- Simple installation. No concrete or roof penetrations required.

- Does not occupy space around the home that could be used for another purpose.

- Relatively low cost if the location is appropriate.

- Installation does not depend on the strength or quality of a roof.

- Orientation and tilt (to some degree) of the modules can be chosen.

Disadvantages

- Site specific. Only typically appropriate for roofs with a low angle (flat).

- Theft can be relatively easy.

- Requires a an appropriate ballast racking structure that either must be bought or custom fabricated beforehand.

- Roof structure must be able to support the additional weight of the concrete blocks.

- Requires a significant amount of concrete blocks to be purchased or fabricated on site.