PV module

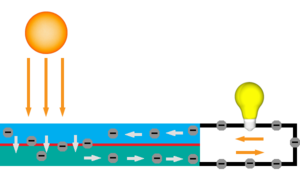

Solar PV modules use the photovoltaic (PV) effect to generate electrical current upon exposure to light. When sufficient light hits a PV cell, current is generated which excites electrons that then pass through a one-way barrier or junction forcing them to flow through a circuit to return to their point of origin. These movement of these electrons can be used to to do work or power loads. There are many different technologies available and ways to design a system that can meet needs that range from simple lighting, to running appliances, pumping water or powering cities.

PV modules are composed of individual cells wired together in series with each one producing around.5V when exposed to sufficient light. PV modules come in serveral common configurations:

- A 36-cell module comprised of .5V cells will have a rated Vmp of around 18V.

- A 60-cell module comprised of .5V cells will have a rated Vmp of around 30V.

- A 72-cell module comprised of .5V cells will have a rated Vmp of around 36V.

Contents

Types

There are many different chemstries that are used in PV cells, but there are two main categories of modules that are found on the market. Each type of solar module continues to have different characteristics that can be attractive depending upon the circumstances such as lower price or higher efficiency.

- Crystalline silicon modules

- The most common type of module on the market. These modules can come in poly or monocrystalline construction. The names are derived from the way that they are manufactured with monocrystalline cells being cut from a single crystal and polycrystalline cells being comprised of silicon from various crystals. Both types are are composed of a few simple materials (average by weight): 76% glass (panel surface), 10% polymer (encapsulant and backsheet foil), 8% aluminium (mostly the frame), 5% silicon (solar cells), 1% copper (interconnectors) and less than 0.1% silver (contact lines) and other metals (mostly tin and lead) [1]

- Monocrystalline modules are more expensive, but achieve higher average efficiencies around 17-20%.

- Polycrystalline modules are less expensive and are less efficient with average efficiencies around 16-17%.

- The most common type of module on the market. These modules can come in poly or monocrystalline construction. The names are derived from the way that they are manufactured with monocrystalline cells being cut from a single crystal and polycrystalline cells being comprised of silicon from various crystals. Both types are are composed of a few simple materials (average by weight): 76% glass (panel surface), 10% polymer (encapsulant and backsheet foil), 8% aluminium (mostly the frame), 5% silicon (solar cells), 1% copper (interconnectors) and less than 0.1% silver (contact lines) and other metals (mostly tin and lead) [1]

- Thin film modules

- Thin film modules are built out by laying photovoltaic material in one or more layers on a supporting material such as glass, plastic, or metal. Thin film modules come in various types with Cadmium-Telluride (CdTe) Being the most common. CdTe modules contain far less aluminum and more glass than Crystalline silicon modules (average by weight): 97% glass (panel surface), ~3% polymer (junction boxes and sealant) and negligible amounts of semiconductors and metals. [1] Thin film modules are far less efficient than crystalline silicon modules at around 9% efficiency, but significantly cheaper.

Standard test conditions

Solar modules are rated in terms of Watts (W) under industry determined laboratory test conditions called Standard Test Conditions (STC). The three conditions are the strength of sunlight called irradiance, cell temperature and airmass. Airmass is fixed for a given location, so it plays a less important role than the other two.

Irradiance

Irradiance is a measurement of sunlight intensity constantly varies throughout the day naturally as the sun moves through the sky, but also due to weather. On a clear day irradiance typically will reach its peak around noon. 1000W/m² is an irradiance value for a clear day around noon, which means that it is not Irradiance can only be measured with specialized and sensitive equipment, but it can be estimated as irradiance has a direct relationship with the current and power that the module outputs. PV module are given their power ratings by testing them at 1000W/m² of irradiance. Irradiance below 1000W/m² reduces cell current and irradiance above 1000W/m² increases cell current. Irradiance can increase beyond 1000W/m² under certain geographic and meteorlogical conditions. The formula for calculating production based upon irradiance is:

Irradiance loss factor = measured W/m² ÷ 1000W/m²

- Example 1: Your PV module is rated at 200W. You measure irradiance at 750W/m² and your PV module is at 25°C. What should the power output of your module be?

- Irradiance loss factor = 750W/m² ÷ 1000W/m² = .75

- Power adjusted for decreased irradiance = 200W × .75

- Power adjusted for decreased irradiance = 150W

- Example 1: Your PV module is rated at 200W. You measure irradiance at 750W/m² and your PV module is at 25°C. What should the power output of your module be?

Cell temperature

Cell temperature is the no more complicated than it sounds - the temperature of the solar cells. Cell temperature can be easily measured and has a direct relationship with voltage. Cell temperatures above 25°C decrease cell voltage and cell temperatures above 25°C increase cell voltage. If cell temperatures are below 25°C, it is possible for a to exceed the modules rated Open Circuit Voltage (Voc). Losses due to increased cell temperature greatly decrease solar cell production in nearly all solar installations. The formula for calculating losses due to increased cell temperatures is:

Temperature loss factor = measured cell temperature - 25°C × temperature coefficient of max power (TkPmp)

- TkPmp is a value from the module specifications sheet and is typically in the form of %/°C.

- Example 1: Your PV module is rated at 200W. You measure cell temperature of 35°C. The module specificiations sheet states that it has a TkPmp of -.48%/°C. What should the power output of your module be?

- Temperature loss factor = 35°C - 25°C × -.48%/°C

- Temperature loss factor = -4.8%. Production will be 94.2% of STC power.

- Power adjusted for high temperatures = 200W × .942

- Power adjusted for high temperatures = 188.4W

- Example 1: Your PV module is rated at 200W. You measure cell temperature of 35°C. The module specificiations sheet states that it has a TkPmp of -.48%/°C. What should the power output of your module be?

Air mass

Air mass is a measurement of the amount of the atmosphere that light from the sun has to pass through before reaching the PV module. It does vary globally, but it isn't relevant here as it isn't a factor that significantly varies for a given location from year to year.

Module ratings

Solar modules will only produce their rated power at their Maximum Power Point, which is Vmp multiplied by Imp, under the Standard Test Conditions laboratory which are not very frequently reached in the real world. Cell temperatures will can quickly rise above 25°C when exposed to sun and 1000W/m² will only be achieved on a clear sunny day. Therefore the curve shown the preceeding graphics will shift depending upon the conditions.

A module is tested and rated based upon the following values which can be found printed on the module or in its specifications sheet:

- Open Circuit Voltage (Voc) – The voltage that the module will produce under STC when it is not connected to a circuit.

- Short Circuit Current (Isc) – The current that a module will produce under STC when it is short-circuited or with its positive output directly connected to its negative.

- Maximum Power Voltage (Vmp) – The voltage that the module will produce when connected to a circuit under STC.

- Maximum Power Current (Imp) – The current that the module will produce when connected to a circuit under STC.

Clearances

PV modules, as seen above, are greatly affected by high temperatures. Therefore properly installing modules to permit ventilation can have a great impact upon system performance. A PV module should not, for example, be placed directly onto a metal roof surface as there will be no ventilation at the back of the module and performance will suffer. In many locations PV modules may experience temperature swings of more than 60°C thoughout the year, which means that space also has to be left for modules to expand and contract, otherwise the glass or cells inside of a module could be compressed and damaged. There are no set rules about how much space to allow around modules or between modules, but there are some guidelines:

- A module should be at least 1cm from a roof surface for optimal performance. Less distance will have a significant impact on performance and more distance will not greatly increase performance. [2]

- The space between modules in an array will typically be determined by the mounting system that is used. At least 10mm between modules is recommended to permit expansion, contraction and adequate ventilation.

Projected life

A well-made silicon solar module will continue functioning over 25 years, although all modules degrade with the passage of time. High-quality modules degrade at an average rate of .5% to 1% per year, whereas poorly made modules degrade even quicker. This is the primary difference between the different costs and qualities of modules.

Maintenance

There are no moving parts in solar PV modules and they are built out of durable materials. The only maintenance that is likely to ever be required a module is an occasionally cleaning if the module is in an area that lacks regular rainfall.

Recyclability

PV modules should be treated as electronic waste and should not be discarded with normal trash. The process for recycling a PV module consists of breaking it down into its main components and then sending them through the appropriate recycling streams. The majority of a crystalline silicon module can be recycled - an estimated 85%.[1] In many areas where PV is being used to facilitate energy access, there are insufficient regulations and therefore a complete lack of a market and infrastructure to handle PV module waste.

Notes

- ↑ 1.0 1.1 1.2 IRENA End-of-Life Management Solar Photovoltaic Panels. https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_IEAPVPS_End-of-Life_Solar_PV_Panels_2016.pdf

- ↑ IJIRSET - Optimization of Air Gap Required Below Solar PV Modules,Mounted on Metal Sheet roof-tops, through Thermal Analysis and Experimental Verification. http://www.ijirset.com/upload/2017/october/75_Optimization.pdf