Módulo FV

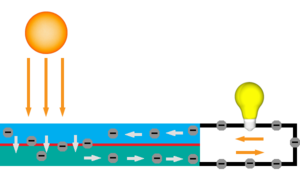

Los módulos solares fotovoltaicos (FV) utilizan el efecto fotovoltaico para generar corriente eléctrica al exponerse a la luz. Cuando la luz llega a una celda fotovoltaica, se genera una corriente que excita los electrones que luego pasan a través de una barrera o unión unidireccional, lo que los obliga a fluir a través de un circuito para regresar a su punto de origen. El movimiento de estos electrones se puede utilizar para realizar trabajos o alimentar cargas electricas como aparatos y luces. Hay muchas tecnologías diferentes disponibles y formas de diseñar un sistema que pueda satisfacer necesidades que van desde iluminación simple hasta electrodomésticos, bombeo de agua o suministro de energía a las ciudades.

Los módulos fotovoltaicos se componen de celdas individuales conectadas juntas en serie y cada una produce alrededor de .5 V cuando se expone a suficiente luz. Los módulos FV vienen en varias configuraciones - las mas comúnes son:

- Un módulo de 36 celdas de .5 V cada uno. Tiene una voltaje de potencia maxima (Vmp) de 18 V.

- Un módulo de 60 celdas de .5 V cada uno. Tiene una voltaje de potencia maxima (Vmp) de 30 V.

- Un módulo de 72 celdas de .5 V cada uno. Tiene una voltaje de potencia maxima (Vmp) de 36 V.

La fuente FV para un sistema autónomo (el módulo FV o los módulos FV en la matriz) deben dimensionarse y seleccionarse junto con el controlador de carga; consulte La fuente FV y la selección y dimensionamiento del controlador de carga para obtener más información.

Contents

Tipos

Hay muchas químicas diferentes que se utilizan en las células FV, pero hay dos categorías principales de módulos que se encuentran en el mercado. Cada tipo de módulo FV sigue teniendo diferentes características que pueden resultar atractivas según las circunstancias, como un precio más bajo o una mayor eficiencia.

- Módulos de silicio cristalino: El tipo de módulo más común en el mercado. Estos módulos pueden venir en construcción poli o monocristalina. Los nombres se derivan de la forma en que se fabrican con células monocristalinas que se cortan de un solo cristal y las células policristalinas están compuestas de silicio de varios cristales. Ambos tipos están compuestos por unos pocos materiales simples (promedio en peso): 76% de vidrio (superficie del panel), 10% de polímero (encapsulante y lámina posterior), 8% de aluminio (principalmente el marco), 5% de silicio (celdas fotovoltaicas), 1% de cobre (interconectores) y menos de 0,1% de plata (líneas de contacto) y otros metales (principalmente estaño y plomo).[1]

- Los módulos monocristalinos son más caros, pero alcanzan eficiencias más altas alrededor del 17-20%.

- Los módulos policristalinos son menos costosos y menos eficientes con eficiencias alrededor del 16-17%.

- Módulos de película delgada: Los módulos de película delgada se construyen colocando material fotovoltaico en una o más capas sobre un material de soporte como vidrio, plástico o metal. Los módulos de película delgada vienen en varios tipos, siendo el telururo de cadmio (CdTe) el más común. Los módulos de CdTe contienen mucho menos aluminio y más vidrio que los módulos de silicio cristalino (promedio en peso): 97% de vidrio (superficie del panel), ~ 3% de polímero (cajas de conexiones y sellador) y cantidades insignificantes de semiconductores y metales.[1] Los módulos de película delgada son mucho menos eficientes que los módulos de silicio cristalino con una eficiencia de alrededor del 9%, pero significativamente más baratos.

Condiciones de prueba estándar

PV modules are rated in terms of watts (W) under industry determined laboratory test conditions called standard test conditions (STC). The three conditions are the strength of sunlight called irradiance, cell temperature and airmass. Airmass is fixed for a given location, so it plays a less important role than the other two. PV modules will only produce their rated power at their Maximum Power Point, which is Vmp multiplied by Imp, under standard test conditions laboratory. These conditions are not frequently reached in most locations as cell temperatures rise quickly when exposed to sunlight and irradiance of 1000 W/m² only occurs when the sky is clear near midday. Therefore, the curve shown the preceding graphics will shift depending upon the conditions.

A module is tested and rated based upon the following values which can be found printed on the module or in its specifications sheet:

- Open circuit voltage (Voc) – The voltage that the module will produce under STC when it is not connected to a circuit.

- Short circuit current (Isc) – The current that a module will produce under STC when it is short-circuited or with its positive output directly connected to its negative.

- Maximum power voltage (Vmp) – The voltage that the module will produce when connected to a circuit under STC.

- Maximum power current (Imp) – The current that the module will produce when connected to a circuit under STC.

- Temperature coefficient of power (P) - A coefficient that accounts for how module power responds to increases and decreases in temperature in %/°C or V/°C.

- Temperature coefficient of open circuit voltage (Voc) - A coefficient that accounts for how module voltage responds to increases and decreases in temperature in %/°C or V/°C.

Irradiance

Irradiance is a measurement of sunlight intensity (power) that constantly varies throughout the day naturally as the sun moves through the sky, but also due to weather. Irradiance measured over time is referred to as insolation and is vitally important for measuring PV system production over time. On a clear day irradiance typically will reach its peak around noon. 1000 W/m² is an irradiance value for a clear day around noon, which means that it is not likely to be normal operating condition in most locations. Irradiance can only be measured with specialized and sensitive equipment, but it can be estimated as irradiance has a direct relationship with the current and power that the module outputs. PV module are given their power ratings by testing them at 1000 W/m² of irradiance. Irradiance below 1000 W/m² reduces cell current and irradiance above 1000 W/m² increases cell current. Irradiance can increase beyond 1000 W/m² under certain geographic and meteorological conditions. The formula for calculating production based upon irradiance is:

| Irradiance loss factor | = measured W/m² ÷ 1000 W/m² |

|---|

Example 1: A PV module is rated at 200 W. Irradiance is measured at 750 W/m² and the temperature of the PV module is measured at 25°C. What should the power output of the module be?

- Irradiance loss factor = 750 W/m² ÷ 1000 W/m² = .75

- Power adjusted for decreased irradiance = 200 W × .75

- Power adjusted for decreased irradiance = 150 W

Cell temperature

Cell temperature is the no more complicated than it sounds - the temperature of the PV cells. Cell temperature can be easily measured and has a direct relationship with voltage. Cell temperatures above 25°C decrease cell voltage and cell temperatures above 25°C increase cell voltage. If cell temperatures are below 25°C, it is possible for a to exceed the modules rated Open Circuit Voltage (Voc). Losses due to increased cell temperature greatly decrease PV cell production in nearly all PV installations. The formula for calculating losses due to increased cell temperatures is:

| Temperature loss factor | = measured cell temperature - 25°C × temperature coefficient of max power (TkPmp) |

|---|

- TkPmp is a value from the module specifications sheet and is typically in the form of %/°C.

Example 1: A PV module is rated at 200W. Cell temperature is measured at 35 °C. The specifications for the module state that it has a TkPmp of -.48 %/°C. What should the power output of the module be?

- Temperature loss factor = 35°C - 25°C × -.48 %/°C

- Temperature loss factor = -4.8%. Production will be 95.2% of STC power.

- Power adjusted for high temperatures = 200 W × .952

- Power adjusted for high temperatures = 190.4 W

Air mass

Air mass is a measurement of the amount of the atmosphere that light from the sun has to pass through before reaching the PV module. It does vary globally, but it isn't relevant here as it isn't a factor that significantly varies for a given location from year to year.

Projected life

A well-made silicon PV module will continue functioning over 25 years, although all modules degrade with the passage of time. High-quality modules degrade at an average rate of .5% to 1% per year, whereas poorly made modules degrade even quicker. This is the primary difference between the different costs and qualities of modules.

Maintenance

PV modules are built out of durable materials and have no moving parts. The only maintenance that is likely to ever be required a module is an occasionally cleaning if the module is in an area that lacks regular rainfall.

Recyclability

PV modules should be treated as electronic waste and should not be discarded with normal trash. The process for recycling a PV module consists of breaking it down into its main components and then sending them through the appropriate recycling streams. The majority of a crystalline silicon module can be recycled - an estimated 85%.[1] In many areas where PV is being used to facilitate energy access, there are insufficient regulations and therefore a complete lack of a market and infrastructure to handle PV module waste.

Notes/references

- ↑ Jump up to: 1.0 1.1 1.2 IRENA End-of-Life Management Solar Photovoltaic Panels. https://www.irena.org/-/media/Files/IRENA/Agency/Publication/2016/IRENA_IEAPVPS_End-of-Life_Solar_PV_Panels_2016.pdf