Difference between revisions of "Charge controller/es"

(Created page with "==Tipos de controladores de carga==") |

(Created page with "File:PWMMPPT201127.png|thumb|right|Una comparación entre el rendimiento de un controlador de carga PWM y un controlador de carga MPPT con una temperatura de celda del módu...") |

||

| Line 33: | Line 33: | ||

==Tipos de controladores de carga== | ==Tipos de controladores de carga== | ||

| − | [[File:PWMMPPT201127.png|thumb|right| | + | [[File:PWMMPPT201127.png|thumb|right|Una comparación entre el rendimiento de un controlador de carga PWM y un controlador de carga MPPT con una temperatura de celda del módulo FV de 20°C]] |

There are two main types of charge controllers used in off-grid PV installations: pulse width modulation (PWM) and maximum power point tracking (MPPT). Both types of charge controllers continue to be popular as each offers distinct advantages depending upon the application. | There are two main types of charge controllers used in off-grid PV installations: pulse width modulation (PWM) and maximum power point tracking (MPPT). Both types of charge controllers continue to be popular as each offers distinct advantages depending upon the application. | ||

Revision as of 12:39, 11 February 2021

El controlador de carga en un sistema fotovoltaico fuera de la red sirve como punto de conexión entre el sistema fuente FV y el almacenamiento de energía. Cada tipo de almacenamiento de energía tiene preferencias específicas de carga y descarga que deben tenerse en cuenta para garantizar una vida útil prolongada (consulte el artículo sobre Baterías de plomo-ácido para obtener detalles específicos). El controlador de carga funciona para administrar la energía entrante de la FV para maximizar la carga cuando las baterías pueden aceptarla y reducirla cuando las baterías comienzan a llenarse. La sobrecarga de una batería hará que los productos químicos y los materiales en la batería se descompongan y generen cantidades significativas de calor, lo que reducirá la vida útil de la batería o dañará permanentemente. La carga insuficiente crónica de una batería es más común y ocurre cuando no se permite que una batería vuelva a un estado de carga completo de forma regular, lo que provocará a una acumulación de sulfatación en las placas de plomo dentro de la batería, lo que con el tiempo reducirá la vida útil de la batería. Un controlador de carga a menudo no puede proteger un sistema de almacenamiento de energía de una descarga excesiva debido al funcionamiento de las cargas, un sistema aútonomo siempre debe incluir un interruptor de baja tensión que esté integrado en el controlador de carga, inversor o es un equipo separado.

Hay una variedad de diseños de controladores de carga diferentes en el mercado que varían mucho en capacidad de voltaje y corriente, rendimiento, funcionalidad y costo. Invertir en un controlador de carga de calidad asegurará la longevidad de los otros componentes en un sistema FV fuera de la red.

El controlador de carga para un sistema fuera de la red debe dimensionarse y seleccionarse en función de la evaluación de cargas para un sitio en particular. fuente FV - ver Resumen del proceso de dimensionamiento y selección de la fuente FV y controlador de carga para más información.

Contents

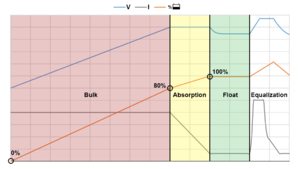

Etapas de carga

Todos los cargadores de baterías para baterías de plomo-ácido, no solo los controladores de carga para sistemas FV, siguen el mismo patrón de carga básico de tres etapas: volumen, absorción y flotación. Un controlador de carga se mueve a través de estas diferentes etapas según los puntos de ajuste de voltaje programados y la temperatura ambiente de la batería o la temperatura ambiente. Los controladores de carga de menor capacidad y menor costo pueden no ofrecer la capacidad de programar los puntos de ajuste de voltaje y dependerán de los valores establecidos por el fabricante. Si el controlador de carga habilita la programación de los puntos de ajuste de voltaje, se debe consultar el manual del usuario para la batería específica ya que los puntos de ajuste de voltaje varían según el fabricante y el tipo de batería (FLA, AGM, celda de gel).

Carga abundante

Cuando una batería tiene un estado de carga de 0 a 80%, el controlador de carga enviará la corriente completa de la fuente FV al banco de baterías para aumentar el voltaje del sistema. El controlador de carga continuará suministrando corriente sin restringirla hasta que se alcance un cierto voltaje, que normalmente es de alrededor de 14,6-14,8 V para una batería de plomo-ácido de 12 V.

Carga de absorción

A medida que la batería se llena, aproximadamente al 80% de la carga completa, el controlador de carga cambia al modo de absorción, momento en el que intenta mantener el banco de baterías al voltaje máximo alcanzado durante la etapa de carga abundundante (~ 14,4-14,8 V para un batería de plomo-ácido de 12 V) utilizando la cantidad mínima de corriente necesaria para hacerlo. La cantidad de corriente requerida para mantenerlo al voltaje fijo disminuye. El controlador de carga continuará en este modo hasta que haya transcurrido un período de tiempo establecido o la cantidad de corriente requerida para mantener el banco de baterías a un voltaje fijo disminuya a un mínimo programado. Esto suele ocurrir en alrededor del 95% de la capacidad de la batería.

Flotación

Una batería que se acerca a la carga completa ya no puede aceptar tanta corriente, por lo que el controlador de carga pasa a la fase de flotación, lo que significa que intenta mantener el banco de baterías a un voltaje más bajo (~ 13.2-13.8 V para una batería de plomo-ácido de 12 V) utilizando la cantidad mínima de corriente necesaria. La carga lenta y gradual puede llevar las baterías a un estado de carga del 100%.

Ecualización

Una carga de ecualización no es una fase de carga estándar, es una sobrecarga planificada de las baterías que puede ayudar a reducir el deterioro a largo plazo de las baterías debido a una acumulación de sufultación en las placas de plomo internas. El voltaje del banco de baterías se puede aumentar hasta ~ 16,2 V durante un período de tiempo específico. No todos los controladores de carga tienen esta capacidad y sólo las baterías de plomo-ácido inundadas pueden someterse a una carga de compensación. El usuario debe programar o activar una carga de ecualización y solo debe realizarse un día con mucho sol ya que la sobrecarga requiere más energía de lo normal. Equilibre las baterías de plomo-ácido inundadas al menos una vez al mes durante 2 a 4 horas, más tiempo si sus baterías se han descargado constantemente. [1]

Tipos de controladores de carga

There are two main types of charge controllers used in off-grid PV installations: pulse width modulation (PWM) and maximum power point tracking (MPPT). Both types of charge controllers continue to be popular as each offers distinct advantages depending upon the application.

Pulse width modulation (PWM)

A PWM charge controller measures the voltage of the battery bank and the temperature (ambient or at the battery bank) to estimate the state of charge of the battery and regulate charging. This type of charge controller can only limit the amount of current that is supplied to the energy storage system. It does not have the ability to vary the voltage of the PV source to get the maximum amount of production like a maximum power point tracking charge controllers. The charge controller and PV source must operate at the voltage of the energy storage system. This means that the PV source may be capable of operating at a higher voltage and supplying more power, but this energy will be lost as this type of charge controller does not offer this functionality.

As the charge controller cannot regulate the voltage of PV source, the modules/array must be designed to work with the voltage of the battery bank. This means that the PV source will have to operate at a relatively low voltage. There are limited module configurations that will work properly with a PWM charge controller:

- A 36-cell module is referred to as a 12 volt nominal module and will be able to supply an appropriate voltage to a 12V battery bank. These modules can be put in parallel to supply more power for a 12V battery bank or can be connected together in series (2 per series string for 24V battery bank and 4 per series string for a 48V battery bank).

- A 72-cell module is referred to as a 24V nominal module and will be able to supply an appropriate voltage to a 24V battery bank. These modules can be put in parallel to supply more power for a 24V battery bank or can be connected in series (2 per series string for a 48V battery bank).

Ratings

A PWM charge controller will be rated in terms of nominal DC system voltage and maximum current. The system designer must choose the appropriate PV source configuration based upon nominal voltage of the battery bank.

- Nominal DC system voltage: 12V, 24V, 48V

- Maximum PV source current: 6A-60A

Maximum power point tracking (MPPT)

A MPPT charge controller works similarly to a PWM charge controller in that it measures voltage of the battery and temperature to determine state of charge and regulate charging. The difference is that an MPPT charge controller can control the voltage of the PV source and the voltage that it supplies to the battery bank using more sophisticated technology and electronics. This can permit higher system performance under a more variable range of conditions and configurations. An MPPT charge controller can accept a variety of different module types and series and parallel configurations.

Ratings

A MPPT charge controller will be rated in terms of nominal DC system voltage, maximum PV source voltage, minimum PV source voltage and maximum PV source current. A system designer will have to design the PV source properly to be able to work within these parameters.

- Nominal DC system voltage: 12V, 24V, 48V

- Maximum PV source voltage: varies up to 600V

- Minimum PV source voltage: depends upon nominal voltage and charge controller type

- Maximum PV source current: up to 100A+

PWM vs MPPT comparison

The right charge controller for every application must be decided upon a variety of different factors:

- Budget - A MPPT charge controller may cost 1.5-2 times as much as a PWM charge controller, although there can be savings if it enables the use of a 60-cell or 72-cell module over a 36-cell module which typically cost more as they are produced in smaller batches.

- Flexibility - PWM charge controllers can only be used with 36-cell or 72-cell modules in specific series and parallel configurations where the operating voltage of the PV source matches the charging voltage of the energy storage system. This limits the PV source to a relatively low operating voltage. Whereas MPPT charge controllers can be used with any series and parallel configurations as long as the maximum voltage and current do not exceed the rating of the charge controller. This flexibility is an very important advantage when designing larger systems.

- Component availability - Certain charge controller types or module types may not be readily available in all locations.

- Performance - MPPT charge controller will perform better in cooler climates as they can take advantage of the higher voltage that a PV module is capable of producing.

- System size - With a smaller system the advantages of a PWM charge controller prevail, but as system size increases the benefits of a MPPT charge controller increase. At a certain system size the additional wiring required with a PWM charge controller due to parallel connections and low voltage becomes a significant pain and expense.

Additional charge controller features

There are many other additional features that charge controllers offer that may be of value on a specific project.

User interface

The user interface is important as it can conveys vital information about the state of charge of the energy storage system, which users need to revise regularly in order to be able to adjust their usage properly and protect the battery bank. A quality user interface and monitoring system can be integrated with a [[Special:MyLanguage/Shunt]shunt]] for more accurate data aobut the state of charge of the energy storage system. Additionally, a user interface should be assessed for how much programming it allows the user to perform and if it allows the revision of historical system data.

Programmability

The larger the power rating of a charge controller, typically the more user programming is permitted to enable customization according to the end user needs. There are basic functions, like the set point for the low voltage disconnect, and other more complicated functions related to battery charging and monitoring. See charge controller programming for more information.

Temperature sensor

Temperature greatly affects the voltage of a battery. The temperature of a battery often varies from the ambient temperature as heat is generated as batteries charge and discharge. Higher quality charge controllers therefore offer the option to connect an additional temperature sensor that can be connected directly to the battery bank in order to enable the charge controller to properly adjust charging based upon battery temperature. This can lead to increased system performance and longevity.

Data logging/monitoring

A data logging/monitoring system can enable the charge controller share or record data about the performance of the system. The level of detail and amount of time for which a charge controller store data varies. Information about energy production and battery bank maximum/minimum voltage can be very useful in assessing how the system is performing in that location, if the user is treating the system properly and resolving any technical issues that may arise. Some systems may also offer the capability of remote monitoring through cell phone signals or the internet, which can be very useful in remote off-grid applications if possible.

Shunt

Many charge controllers can function with a shunt to enable more accurate measurement of battery bank state of charge (SoC). The information provided by a shunt is more accurate and can allow the users to better manage and take care of their system.

Lighting controller

Many charge controllers for smaller off-grid PV systems include a DC lighting control circuit that can be used to help protect the battery bank. All systems should have some type of low voltage disconnect in order to protect the battery bank and an integrated lighting controller in a charge controller can meet this need. A lighting controller in its simplest form may automatically disconnect lights and DC loads at a certain battery voltage or in more complicated forms can be programmed to automatically turn on and run lighting loads during certain hours.

Projected life

There is no specific projected life for a charge controller as it varies significantly based upon quality and conditions of use. A low-quality charge controller may only last six months before failing, whereas a high-quality charge controller used under optimal conditions could last decades. Higher cost does not always directly translate into a high-quality charge controller, as there are very cheap PWM charge controllers on the market that are extremely well-built and durable.

Maintenance

The user manual for a charge controller should always be consulted, but most charge controllers do not require much maintenance if they are used under proper conditions. They should be kept free of dust, insects, and water. Connections should be periodically revised - at least once a year - to make sure that they are still tightened properly and not creating unnecessary resistance.

Recyclability

Charge controllers contain a variety of different materials and chemicals that can be hazardous if not disposed of properly - they should be treated as electronic waste.

Notes/references

- ↑ Trojan Battery Company - Battery Maintenance https://www.trojanbattery.com/tech-support/battery-maintenance/