Difference between revisions of "Conductor size"

Jump to navigation

Jump to search

| Line 5: | Line 5: | ||

#The amount of voltage that will be lost under operation, which is called [[voltage drop|voltage drop]] | #The amount of voltage that will be lost under operation, which is called [[voltage drop|voltage drop]] | ||

| − | The wires for an off-grid system must will be sized and selected based upon the [[Load evaluation|load evaluation]] and the [[Physical evaluation|physical evaluation]] for a particular site. This process must be done in conjunction with the sizing and selection of the [[:Category:Overcurrent protection|overcurrent protection device]] - see [[:Category:Wire and overcurrent protection sizing and selection|Wire and overcurrent protection sizing and selection]] for more information. | + | The wires for an off-grid system must will be sized and selected based upon the [[Load evaluation|load evaluation]] and the [[Physical evaluation|physical evaluation]] for a particular site. This process must be done in conjunction with the sizing and selection of the [[:Category:Overcurrent protection and disconnects|overcurrent protection device]] - see [[:Category:Wire and overcurrent protection sizing and selection|Wire and overcurrent protection sizing and selection]] for more information. |

The two most common standards for wire size are American Wire Gauge (AWG) and mm². These two systems are not directly equivalent. | The two most common standards for wire size are American Wire Gauge (AWG) and mm². These two systems are not directly equivalent. | ||

Revision as of 12:14, 27 November 2020

Wires come in standard sizes depending upon the location. The proper wire size for a particular circuit depends on two important considerations:

- The amount of current that they can safely carry given the conditions in which they will be used, which is called wire ampacity.

- The amount of voltage that will be lost under operation, which is called voltage drop

The wires for an off-grid system must will be sized and selected based upon the load evaluation and the physical evaluation for a particular site. This process must be done in conjunction with the sizing and selection of the overcurrent protection device - see Wire and overcurrent protection sizing and selection for more information.

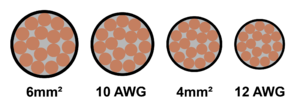

The two most common standards for wire size are American Wire Gauge (AWG) and mm². These two systems are not directly equivalent.

| Standard AWG | Metric equivalent | Standard metric equivalent (mm²) |

|---|---|---|

| 18 AWG | .82 mm² | 1 mm² |

| 16 AWG | 1.31 mm² | 1.5 mm² |

| 14 AWG | 2.08 mm² | 2.5 mm² |

| 12 AWG | 3.31mm² | 4mm² |

| 10 AWG | 5.26 mm² | 6 mm² |

| 8 AWG | 8.37 mm² | 10 mm² |

| 6 AWG | 13.3mm² | 16mm² |

| 4 AWG | 21.2 mm² | 25 mm² |

| 3 AWG | 26.7 mm² | |

| 2 AWG | 33.6 mm² | 35 mm² |

| 1 AWG | 42.4 mm² | 50 mm² |

| 1/0 AWG | 53.5 mm² | |

| 2/0 AWG | 67.4 mm² | 70 mm² |

| 3/0 AWG | 85 mm² | 95 mm² |

| 4/0 AWG | 107 mm² | 120 mm² |