Difference between revisions of "Lithium-ion battery"

| Line 9: | Line 9: | ||

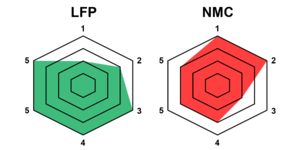

[[File:Lithiumcomparison.png|thumb|'''Diagrams comparing different lead acid battery types. The outermost ring is the highest rating/performance. Innermost ring is the lowest rating/perfomance.'''<br/> ''(1)'' Energy density ''(2)'' Power density ''(3)'' Safety ''(4)'' Toxicity ''(5)'' Cycle life ''(6)'' Cost]] | [[File:Lithiumcomparison.png|thumb|'''Diagrams comparing different lead acid battery types. The outermost ring is the highest rating/performance. Innermost ring is the lowest rating/perfomance.'''<br/> ''(1)'' Energy density ''(2)'' Power density ''(3)'' Safety ''(4)'' Toxicity ''(5)'' Cycle life ''(6)'' Cost]] | ||

Lithium iron phosphate (LFP) and Lithium nickle manganese cobalt (NMC) each have distinct advantages that lend themselves to different applications. | Lithium iron phosphate (LFP) and Lithium nickle manganese cobalt (NMC) each have distinct advantages that lend themselves to different applications. | ||

| − | + | ====LFP==== | |

| − | ====LFP==== LFP batteries have emerged as the preferred technology for stand-alone applications as they offer several advantages when compared to NMC batteries: a longer cycle life, a lower price point per kWh, a less toxic chemistry, and a lower probability of thermal runaway events. The characteristics of LFP batteries enable manufacturers to build smaller batteries that can function as drop in replacements for lead acid batteries in many different systems. | + | LFP batteries have emerged as the preferred technology for stand-alone applications as they offer several advantages when compared to NMC batteries: a longer cycle life, a lower price point per kWh, a less toxic chemistry, and a lower probability of thermal runaway events. The characteristics of LFP batteries enable manufacturers to build smaller batteries that can function as drop in replacements for lead acid batteries in many different systems. |

====NMC==== | ====NMC==== | ||

Revision as of 14:28, 1 January 2021

Lead acid batteries continue to be the standard for energy storage systems globally due to their low cost, reliability, and availability. Lithium ion batteries are beginning to be used more frequently in energy storage systems as they offer several appealing characteristics for stand-alone PV applications. There are a variety of different lithium ion chemistries, but there are two in particular that have emerged as the most popular technologies for stand-alone PV applications: lithium iron phosphate (LFP) and lithium nickel manganese cobalt (NMC).

Lithium ion batteries are composed of many small cells that are wired in series and parallel to achieve a desired nominal voltage. These cells are very sensitive to over-charging and therefore require a battery management system (BMS) to ensure proper battery charging. Improper charging can not only irreparably damage the batteries, but can also lead to a thermal run-a-way event with NMC batteries in which the temperature of a battery can no longer be controlled and rises to the point that equipment is destroyed or a fire is started.

The design of lithium ion batteries and the presence of a BMS systems means that the batteries are designed to function at a set nominal voltage and are not intended to be wired in series like is done with lead acid batteries. They are sold in 12 V, 24 V, and 48 V nominal voltages that can be wired in parallel to achieve the desired Ah or kWh capacity. One of the advantages of the the BMS systems that accompany each battery is that proper charging is ensured for all batteries connected in series meaning that there is typically no limited to the number of batteries that can be put in parallel like exists with lead acid batteries (it is best to limit the number of lead acid batteries in parallel to no more than three strings to ensure proper charging).

Contents

Lithium ion battery types

Lithium iron phosphate (LFP) and Lithium nickle manganese cobalt (NMC) each have distinct advantages that lend themselves to different applications.

LFP

LFP batteries have emerged as the preferred technology for stand-alone applications as they offer several advantages when compared to NMC batteries: a longer cycle life, a lower price point per kWh, a less toxic chemistry, and a lower probability of thermal runaway events. The characteristics of LFP batteries enable manufacturers to build smaller batteries that can function as drop in replacements for lead acid batteries in many different systems.

NMC

The main advantage of NMC batteries is that they have a higher energy density (can store more energy for the same volume/weight) and can function with higher charge/discharge currents. NMC batteries are typically found in larger integrated systems like those built by LG Chem and Tesla.

Compatability with other equipment

It is important to make sure that any equipment used with lithium ion batteries is compatible with them. They have different parameters/voltages than lead acid batteries that will require additional programming. These parameters vary significantly from manufacturer to manufacturer - consult the manual or manufacturer of any battery being considered.

Recycleability

Comparison with lead acid batteries

Lithium ion batteries have both advantages and disadvantages with compared with lead acid batteries.

Advantages:

- Higher energy density. They can store significantly more energy in the same space/weight.

- Longer cycle life. They can provide 2-3 times as many cycles as lead acid batteries.

- Higher round trip efficiency. 95-98% as compared to 80-90% efficiency for lead acid batteries.

- Higher depth of discharge. 80-100% with each cycle is possible as compared to recommended maximum of 50% with lead acid batteries.

Disadvantages:

- Higher upfront investment. Although the cost per cycle of some lithium ion energy storage systems is comparable to that of lead acid batteries.

- Very sensitive to over-discharging and over-charging. The amount of current that can be inputted/outputted is limited and if exceeded can irreparably damage the batteries.

- Require a battery management system.

- Risk of thermal runaway events.

- Far more sensitive to low temperatures. Cannot be charged below 0°C.

- Limited availability.

- Limited compatible equipment availability.