Difference between revisions of "Grounding system"

| Line 18: | Line 18: | ||

*'''Grounding electrode''' - The connection point between the earth and the electrical system. There are many different types of electrodes - copper rods, steel rods, a copper plate, the metallic pipes of a building, or a proper connection to the rebar used in the foundation of a building. | *'''Grounding electrode''' - The connection point between the earth and the electrical system. There are many different types of electrodes - copper rods, steel rods, a copper plate, the metallic pipes of a building, or a proper connection to the rebar used in the foundation of a building. | ||

| − | *'''Grounding electrode conductor''' - The connection that runs from the grounding electrode to the location of the rest of the electrical equipment - typically a wire that runs from the grounding electrode to a grounding [[ | + | *'''Grounding electrode conductor''' - The connection that runs from the grounding electrode to the location of the rest of the electrical equipment - typically a wire that runs from the grounding electrode to a grounding [[Busbars|busbar]] in the main distribution panel. |

| − | *'''Equipment grounding conductor''' - The connection that runs from the grounding [[ | + | *'''Equipment grounding conductor''' - The connection that runs from the grounding [[Busbars|busbar]] in the main service panel to all of the non-current carrying metallic components of a system (conduit, inverter housing, charge controller housing, enclosures, etc.). |

| − | *'''AC system bonding jumper''' - The connection between an AC current carrying conductor in an electrical system and the grounding electrode conductor - typically a wire in the main distribution panel that runs from the grounding electrode conductor [[busbar]] to the grounded conductor [[ | + | *'''AC system bonding jumper''' - The connection between an AC current carrying conductor in an electrical system and the grounding electrode conductor - typically a wire in the main distribution panel that runs from the grounding electrode conductor [[busbar]] to the grounded conductor [[Busbars|busbar]]. There are some inverters that come with a pre-established internal system ground, for example any that come with an integrated [[Ground fault protection device|ground fault protection device (GFPD)]]. A second system ground should not be created. |

*'''DC system bonding jumper''' - The connection between a DC current carrying conductor in an electrical system and the grounding electrode conductor - commonly made through a [[Ground fault protection device|ground fault protection device]]. | *'''DC system bonding jumper''' - The connection between a DC current carrying conductor in an electrical system and the grounding electrode conductor - commonly made through a [[Ground fault protection device|ground fault protection device]]. | ||

Revision as of 08:48, 29 November 2020

A grounding system creates a low-resistance connection between system equipment and/or a system conductor - called a neutral or grounded conductor - to the earth by using a grounding electrode. A grounding system is not necessary for an electrical system to function, the electrical distribution systems in some countries lack any type of grounding and others have complex grounding systems with additional measurement devices to protect users. In offgrid installations, it is common for small-scale DC-only PV systems operating at below 50 V to lack a grounding system as it would increase the cost substantially without providing significant benefit. As system size, voltage, and cost increase the benefits of a grounding system grow. The electrical code for every country will contain information about the requirements and appropriate equipment for that location.[1]

Additionally, it is necessary to consult the manual for any charge controller or inverter before deciding upon a grounding scheme as they may have different requirements for grounding. There are a few cases that are worth noting here:

- There are some small inverters - modified sine wave and square wave - that will be destroyed if they are connected in a system that has both an AC and a DC system ground as they do not properly isolate their DC input from the AC output.

- There are some charge controllers that are intended for specific applications, like remote telecommunications installations, that are positively grounded.

TN-S grounding system

The preferred grounding system for the majority of off-grid systems is called a TN-S system, which has a grounded conductor (neutral) and a seperate equipment ground that is run with each circuit to bond together non-current carrying metal parts of the system (enclosures or major system components).[2] A TN-S grounding system carries has two main components that work together:

- System grounding - System grounding is created by connecing one current-carrying conductor of an electrical system to ground. A proper system ground provides a means to dissipate excess static electricity created by friction or lightning. This helps to create a stable system voltage and protect system equipment from damage.

- Equipment grounding - Equipment grounding is created by connecting all non-current carrying metallic components of a system to ground. Thise creates a path for any current created by a fault - due to failure of insulation or a loose connection - to return through the equipment grounding or the earth to the grounded conductor.

Components of a TN-S grounding system

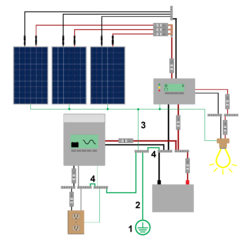

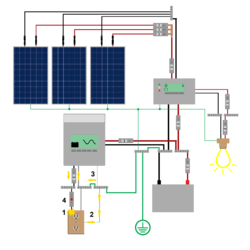

1. The ungrounded conductor touches a grounded piece of equipment. 2. The equipment grounding conductor carries the current back to the busbar. 3. The system bonding jumper connects the ungrounded conductor to the grounded conductor. 4. A low resistance path for current to flow is created. Current surges from the inverter and the overcurrent protection device for the circuit opens (disconnects) the circuit.

A proper grounding system requires various different components that are connected together in order for the system to work effectively and safely.

- Grounding electrode - The connection point between the earth and the electrical system. There are many different types of electrodes - copper rods, steel rods, a copper plate, the metallic pipes of a building, or a proper connection to the rebar used in the foundation of a building.

- Grounding electrode conductor - The connection that runs from the grounding electrode to the location of the rest of the electrical equipment - typically a wire that runs from the grounding electrode to a grounding busbar in the main distribution panel.

- Equipment grounding conductor - The connection that runs from the grounding busbar in the main service panel to all of the non-current carrying metallic components of a system (conduit, inverter housing, charge controller housing, enclosures, etc.).

- AC system bonding jumper - The connection between an AC current carrying conductor in an electrical system and the grounding electrode conductor - typically a wire in the main distribution panel that runs from the grounding electrode conductor busbar to the grounded conductor busbar. There are some inverters that come with a pre-established internal system ground, for example any that come with an integrated ground fault protection device (GFPD). A second system ground should not be created.

- DC system bonding jumper - The connection between a DC current carrying conductor in an electrical system and the grounding electrode conductor - commonly made through a ground fault protection device.

System grounding and equipment grounding work with overcurrent protection devices, ground fault protection devices, residual current devices and inverter electronics to identify faults and disable them as quickly as possible by opening (disconnecting) the circuit. This system functions because a fault to an equipment grounding conductor will create a short-circuit if there is low enough resistance, which will activate these devices and cause them to open (disconnect) the circuit.

Notes/references

- ↑ Cahiers Techniques 173: Earthing Systems Worldwide and Evolutions https://www.mikeholt.com/documents/mojofiles/electricalearthingworldwide.pdf

- ↑ SMA Grounding in Off-grid Systems: Design of TN and TT Off-Grid https://files.sma.de/downloads/SI-OffGrid-Grounding-TI-en-11.pdf